insoles making process starts with a fine tuning of the sample jig that requires mastery and deep material knowledge to prevent issues during further mounting of the shoe.

insoles making process starts with a fine tuning of the sample jig that requires mastery and deep material knowledge to prevent issues during further mounting of the shoe.

after a rough jig shaping the sample insole is monitored and verified with the shoes’ mould to fine-tune all details. Solettificio Monica proudly puts into practice 40 years of experience in this delicate and important phase.

customers can also provide their own .dxf cad model.

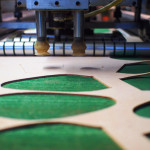

the final insole sample is then scanned and digitally processed with CAD-CAM and sent to cutting machinery that trims all insoles’ components like texon, fireboard and cuoio leather.

as components are ready to be put together all insoles parts are manually assembled together with shanks and verified singularly

assembled insoles are mechanically pressed to ensure components tightness even after intesive shoes usage.

finally all insoles banded together are ready to be send to shoes factory for final assembly.